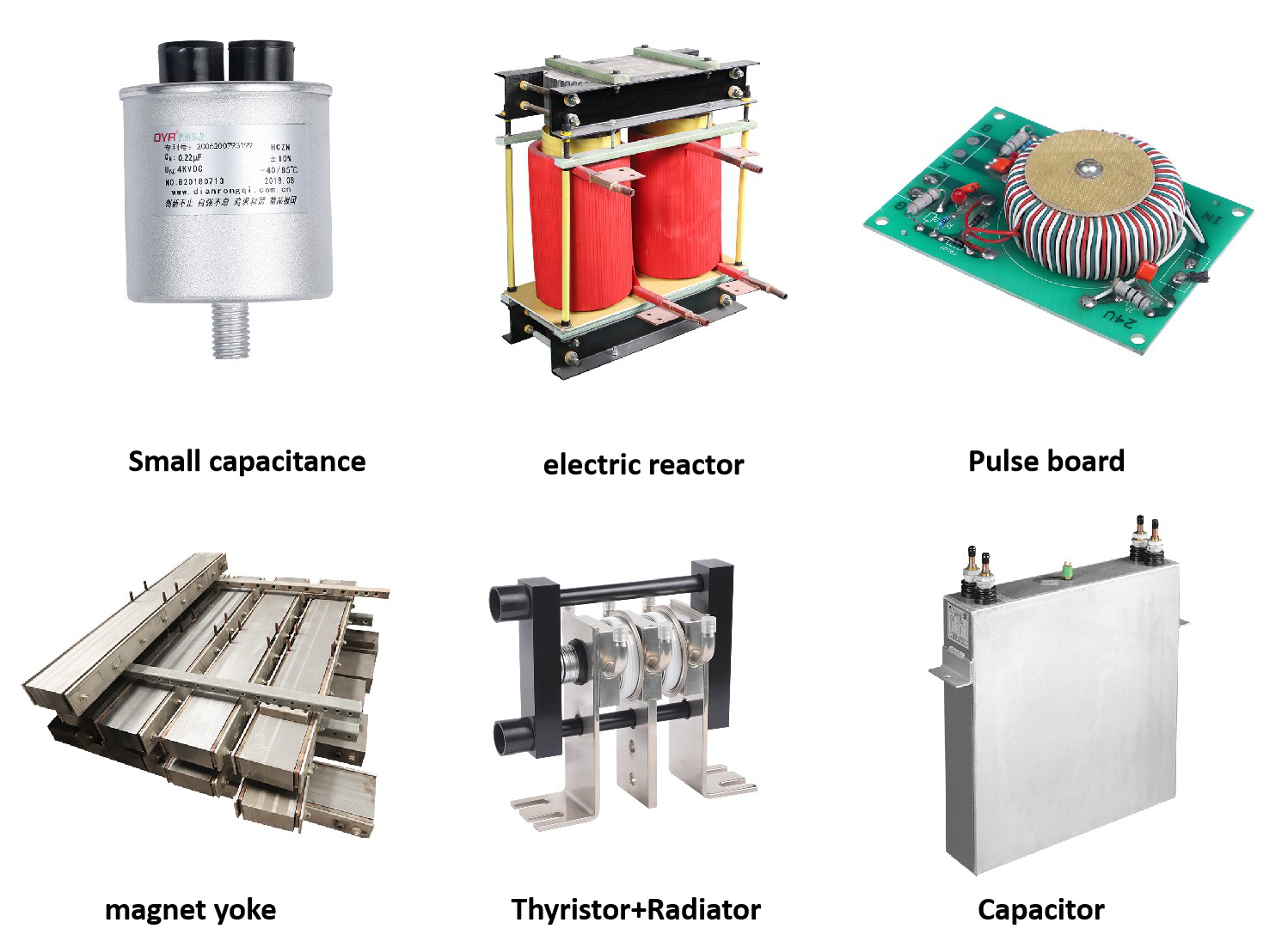

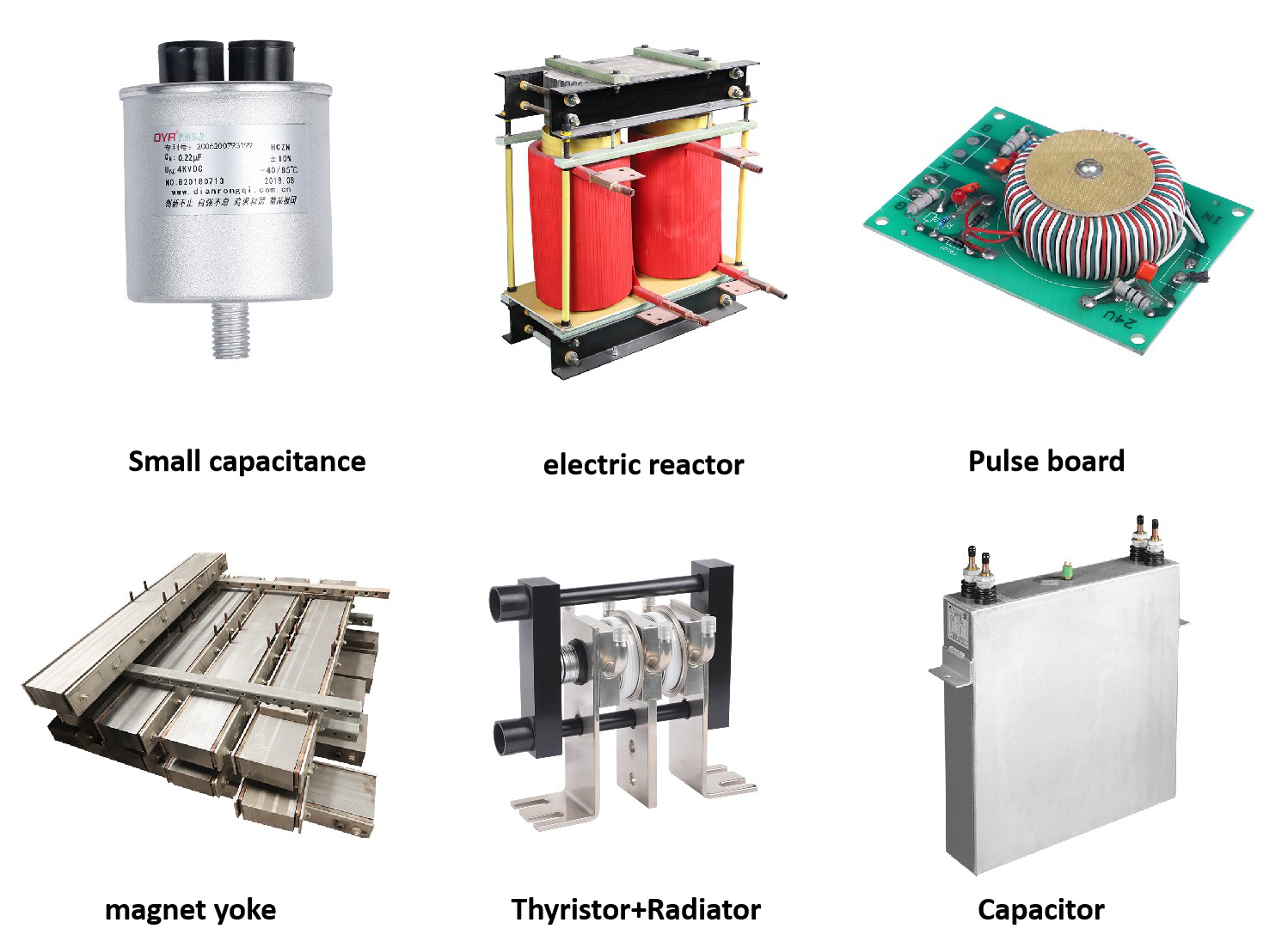

RFM0.75-1000-0.25S

Water Cooled Capacitor for smelting furnace

has leveraged two generations of

water cooled capacitor design and op�

erational expertise to produce our WFC

Series capacitors for a wide range of in�

duction heating applications, to include

melting, forging, billet heating, harden�

ing, and other types of heat treating.

With our expanded, Class 10000 clean

room manufacturing capabilities, we can

develop any solution for your induction

heating power supplies, regardless of

size.

We now offer our new Jumbo CanTM

high performance capacitors for low

frequency and high voltage AC resonant

tank circuits.

Water Cooled Designs

Description/Specification/Construction:

• Designed for use in AC tank circuits or specialty DC filter circuits

• All-film or metallized film dielectric

• Tin-plated, copper terminals rated for up to 300 Amps continuous

• Electrical grade phenolic bushings for indoor application

• Long life, 20 year nominal life

• Low loss, less than 0.3 watts per kVAR up to 5 kHz;

less than 0.5 watts per kVAR up to 50 kHz

• Special dielectric system designs for high efficiency

• dielectric fluids; Dielektrol VI for metallized delectrics, Dielektrol VIIa for

all-film dielectrics

• Designs that employ a pressure switch are supplied with a N/C, 12 PSI,

non-resetting switch. All metallized dielectric designs require a pressure

switch

• Case design: textured aluminum using 0.60 in. (15.25mm) to 0.90 in.

(22.85mm) aluminum, with 0.125 in. (3.18mm) base and cover

• Brackets when included have .50 in. (12.7mm) and 0.625 in. (15.9mm)

mounting slots

• GE requires that equipment manufacturers use the recommendations

specified in bulletin GEH-2733 concerning outlet water temperature, water

flow rate and water cleanliness in design and operation of their equipment

Intermediate frequency furnace super capacitor 750V RFM0.75-1000-0.25S

Electric heating capacitor

RFM electric heating capacitor is mainly used in medium frequency induction heating electrical system to improve the power factor or circuit characteristics.Electric heating capacitor is mainly composed of core and shell, which is filled with high quality macerating agent, core is welded with cooling water supply container for cooling.